- safety glasses

- #2 phillips head screwdriver

- wrenches

- 16mm or 5/8"

- '94 & LATER - 17mm or 11/16"

- 2 - 9/16"

- 10mm

- drill w/ 3/8" drill bit (an angle drill with a short bit is

helpful but not absolutely necessary)

- jack and jack stands

- fine tooth reciprocating saw or jigsaw for cutting package shelf and

fitting plastic interior

panels (a belt sander and/or half round file are also helpful)

- T-40 torx drive for removable hard top latches

- 3/4" holesaw if you have antilock brakes and are installing an M1

Sport or Hard Core Hardtop

1) Put the top down.

2) REMOVE THE TRIM PANELS COVERING THE SEAT BELT TOWERS. (THESE

PIECES ARE CALLED QUARTER TRIM BY MAZDA.)

First remove the metal cap at the top of the panel just behind the door.

This is held in place by a threaded fastener that is used to attach the

top boot (10mm) and a Phillips head screw on the NA. The NB

version is similar but an extra rubber molding has been added that is

held in place by a plastic insert inside the top of the door jamb and another

under the lip of the body just behind the door.

Remove the weather-stripping that runs along the front edge of the trim

panel at the rear of the door opening. (you might find it necessary to

loosen the 4 Phillips head screws in the scuff plate that runs along the

bottom of the doorsill on some early models)

Remove the plastic cover from the shoulder harness guide (it just snaps

off), loosen the bolts and remove the bolt and spacers from the guide.

On the '94-'97 models Remove the cockpit brace end covers (they also snap),

loosen the bolts and remove the cockpit brace.

There is a small plastic clip at the rear of the trim panel just behind

the hole the shoulder harness guide bolt goes through. Remove the clip

by pulling it toward the rear of the car.

Remove the rectangular seat belt trim ring at the front of the panel

and the 2 fasteners in each trim panel located on the inside just above

the package tray, one is a kind of plastic rivet that is loosened by

lifting the center portion and pulling it free, the other is another of

the boot cover snaps with the 10mm head. If you have an NB with the

wind blocker, remove the screws and lift the wind blocker out. The trim

panel can now be removed by pulling it toward the center of the car, there's

a couple of snap type fasteners down low just behind the door that you

will need to pop loose as the panel is pulled free.

3) PUT THE TOP UP - Loosen the carpet from the front of the

package shelf behind the seats and

fold it back. A claw hammer is a good tool for removing the plastic carpet

fasteners. Lower the top. (Pre '99 leave the window zipped in, be careful

not to crease the plastic window) Some sort of cover for the window is

not a bad idea. Remove the large silver metal panel that makes up the

front part of the package shelf by removing the several bolts w/ 10mm

heads that hold it in place and releasing any wire loom fasteners. Lift

the cover up and out of the car. Remove the insulation pads on either

side of the fuel tank cover.

On the '94-97 models there's a computer mounted behind the passenger seat,

the outer mounting bracket will need to be modified and the upper mounting

stud removed to allow clearance for the roll bar mounting plate. (FIG#

8)

If you are installing an M1 SPORT or any version HARD CORE

HARDTOP: Trim the package shelf area just behind

the fuel tank cover opening as shown in (FIG#

5). You will also need to remove the spare tire and the metal

panel at the front of the trunk on the driver's side (the one with the

jack handle attached) if you are working on a pre '99.

While it's not absolutely necessary to do so, I find it helpful to

remove the front trunk panels in the NB, they are held in by several plastic

push-pin rivet fasteners.

If the car has antilock brakes and you are installing an M1 SPORT or a HARD CORE HARDTOP:

Relocate the ABS sensor wiring harnesses. Jack up the rear of the car and

support with sturdy jack stands. Remove the wheels and the plastic inner

splash panels. The harnesses run from the sensors, mounted next to the

brake rotors, up through rubber bulkhead plugs in the areas just to either

side of the fuel tank. Trace the harnesses forward to the connectors just

behind the seats, on either side of the area just uncovered by removal of

the package shelf panel. Unplug the connectors, untangle the harnesses

from the wire holders and other wiring, push the bulkhead plugs through

and pull the wires out under the car. After the roll bar is bolted

in, using a holesaw, open a 3/4" hole just far enough to the front or rear of the foot

plate to clear, reroute the wiring and reinstall the bulkhead plugs

4) REMOVE THE LOWER SEAT BELT REEL BOLTS (16mm pre'94 17mm '94

and later) AND SPACERS. Also remove seat belt reel alignment screw at

the top of the mounting bracket (small screw w/ 10mm head) and discard. Pull the complete

assembly forward and bend the alignment tab down flat, this will allow

the reel to tilt inward for better seat belt alignment and retraction

after the bar is installed. Do not reinstall the small alignment

bolt at the top of the reel.

VERY IMPORTANT GO TO SEAT

BELT REEL & GUIDE INSTRUCTIONS and follow these instructions.

Make certain the area where the rear mounting plates attach is

clear of all body caulk and weld spatter allowing the rear plates to sit

flat down on the panel.

5) SET THE BAR IN THE CAR - BE CAREFUL The rear brace foot

plates will just fit under the front edge of the package tray, work the

rear braces past the several wiring harnesses and battery cables in this

area being careful not to damage any of the wiring. Also watch the front

mounting plates, they will be very close to the seat backs at this point.

The horizontal mounting plates half way up the bar should fit over the top

of the seat belt tower and align with the bolt hole that held the shoulder

harness guide. The lower mounting points align with the lower seat

belt reel bolt holes. The roll bar plates fit against the seat belt reels

which stay in their original location but do not use the original spacers.

(FIG# 1) Once the bar and the seat belt reels are in position, start but do not completely

tighten the seat belt reel mounting plates using the bolts from the hardware kit

and the original equipment small OD flat washers from the stock bolts. Make sure that your seat belts are on the inside of the roll bar. On

some cars the captive nut for the belt reel bolt will not be exactly

vertical and will make threading the bolt difficult or impossible with the

bar installed. Use a large Phillips screwdriver or tapered bar working

through the roll bar mounting slot to align

the nut.

6) Using the bolts and spacers from the hardware kit, install the upper mounting

bolts through the upper mounting plate with the spacer under the plate

in place of the original shoulder harness guide bolt and spacers, (FIG#

2). If you have a problem with alignment partially tighten the seat

belt reel bolts and pull the rear braces toward the rear by reaching through

from the trunk or pry back on the front of the bar to make the bolt

align. Do NOT slot the hole in the roll bar plate.

Most of the time

this is not a problem but we've noticed over the years that NA and NB

seat belt towers tend to vary. In some instances, by a considerable amount

even from side to side in the same car. If the spacer is too long for your

car, it will make the bolt difficult to align and hold the rear plates off

the pan. Too short and the plate will distort when you tighten the bolt.

Cut the spacer or add a washer or two if needed. The spacer should be a

snug fit under the plate but should not hold the rear of the bar up.

Be sure the trim cap mounting washers are under the bolt

heads, we want this thing to look nice when you get done!

The shoulder

harness guide is NOT installed at this point, DO NOT install the guide

under the mounting bolt.

Attach the seat guide to the bar through the smaller, more forward hole

in the upper mounting plate using the bolts, washers and bushings supplied

in the hardware kit as shown in (FIG# 3) Be careful, don't

drop any hardware down in the seat belt reel. Tighten to 20 ft-lbs.

Once

you have the seat belt reel and the upper mounting plate bolts started

and no wires are pinched tighten the reel and tower bolts to 40 ft-lbs

7) JACK UP THE REAR OF THE CAR AND SUPPORT WITH STURDY JACK

STANDS - Remove the wheels and plastic splash panels from the front of the

inner fenders. (pre 99 - 4 bolts w/ 10mm heads / NB - 4 plastic fasteners w/

Phillips heads)

8) GET THE DRILL AND SAFETY GLASSES - Install the rear

plates and tighten the rear of the bar FIRST.

Locate the position for

the rear back-up plates by drilling the first hole down from the top if

you have an angle drill.

If you don't have an angle drill, heavily center punch through one of

the outer mounting plate holes. You should be able to feel the punch mark

from under the wheel well to locate the hole location. Drill fron under

the car using a standard drill. Once you get the first hole drilled, bolt

the back-up plate in place. The others can be done from under the car

using the back-up plate as a template. (FIG#

6) The flanged locknuts do not require a washer. Use the supplied

washers under the bolt heads. We want the reinforcement plate to wedge

tightly against the unibody rail. Drill at and angle if necessary, put the

bolt through and tighten. Do NOT cut down the plates.

Save the easy part for last. Drill through the lower main hoop plates

and bolt the back-up plates in place using washers under the bolts. You

will notice a purpose built gap between the lower front plates and the

bulkhead. Not a problem. Install the bolts though the bar, panel and

reinforcement plates, tighten to 33

ft-lbs and let the bolts close the gap.

On the NB, part of the evaporative emission system is located in

the wheel well on the passenger side. A snap fastener holds a small

filter just behind the battery cable grommet and the front plumbing is

held by a 10mm hex head fastener, loosen for roll bar installation.

Reinstall the front fastener and relocate the small filter by tucking it

behind the wiring harness after the back-up plate bolts are tightened or

drill a 1/4" hole and snap it back into the pan forward of the roll bar

plate. The filter does not have to be vertical and there's no fuel to

leak.

Spraying the back-up plates with undercoating after the fasteners

are tight is a good idea. Install the splash panels, rear tires, trunk

panels and spare.

9) Check convertible top clearance - it may be necessary to adjust

the top frame to allow clearance when the top is lowered and raised especially

with the covered bars. Raise the top slowly checking clearance as the

hinge points come up past the bar. If the hinge points rub loosen the

(3) bolts with 12mm heads behind either doorjamb that hold the top frame.

Pull the frame as far to the rear as possible, you might need to lift

the top slightly to allow more movement. Tighten the bolts while holding

pressure on the top and recheck clearance. See

convertible top adjustment page. These adjustments will not cause

problems with top fitment at the windows or windshield but will keep the

top frame from scratching the bar or cover.

10) TRIM THE PACKAGE SHELF PANEL and reinstall - On the pre 99's it's a small notch

at the rear corners.

The NB requires a notch on either side, use the bolt holes for reference

points. Bend the rear corners to clear the bar until the panel is in place

then flatten into place. Install the package shelf panel, raise the top put

the carpet back in place and trim around the roll bar. Cut the carpet in

a series of pie-shaped wedges and tuck it down around the rear braces of

the bar.

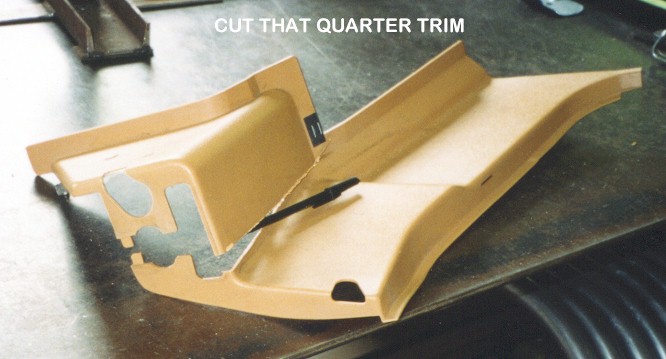

11) CUT QUARTER TRIM PANELS - In

order to reinstall the trim panels they have to be cut into two pieces,

it's not really all that bad, it just takes some time to do it right.

I use a small air powered reciprocating saw to do the dirty work, but

a fine tooth jigsaw, Dremel or hacksaw will do. It's

fairly evident as to where the cut needs to be made, just cut the panel

and trim to fit up to the roll bar, but maybe (FIG#

4b) will help to make things easier. A belt sander gives a nice

straight finished edge but a large fairly coarse (wood type) file will

suffice. Take several small cuts to get a good fit, you can always take

more off but you can't put it back. In addition to the vertical cut, a semicircular

area will have to be removed along the outer top area of the panel to

fit up to the bar. (FIG# 4a)

The final cut is to elongate the seat belt hole, trim to the vertical

edge, cut the end off of the rectangular seat belt trim rings that were

snapped out of the quarter trim during the disassembly so that they will

fit back into the elongated seat belt holes and butt up against the roll

bar. (FIG# 4a) Make sure the

seat belt does not drag against the panel.

12) If you are installing a HARD CORE HARDTOP version you will need to grind, sand or file off the rear edge of the hard top side latch hook that mounts to the body just behind the door jamb. Hold the latch hook up to the bar and mark it with a grease pencil. The bar sits at a slight angle requiring more material to be removed on the lower rear edge and tapering toward the top.

13) REINSTALL THE REMAINING PARTS - The NB windblocker is not

compatible with the Xtreme, M1 Sport or Hard Core Hardtop. It can be

reinstalled with the M2 Sport and clears when up or down but the flap will

contact the bar in transition.

Front View

|

Quarter Panel Initial Cut

|

|

|

| WARNING: This article is sold without warranty,

expressed or implied. No warranty is made to this product's ability

to protect the user from any injury or death. The user assumes that

risk. |

Updated

January 26, 2018 7:17 PM

|